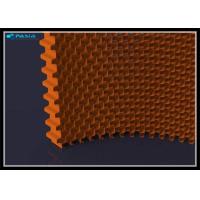

Impact Energy Absorber Aluminum Honeycomb Core for Vehicle Industry

Impact Energy Absorber Aluminum Honeycomb Core for Vehicle Industry

is a specially developed aluminum honeycomb core product for the

impact energy absorber for the sporting or vehicle industry. There

is a sceintific research and test showed: velocity sensitivity of

aluminum honeycomb under high-speed axial impact in a velocity

range from 20 to 80 m/s. Series experiments were carried out with

the help of self-developed high-speed impact system. Afterwards,

corresponding numerical simulation works as well as some parametric

studies were conducted. The resultant comparison told out that the

plateau stress increases markedly when impact below 30 m/s, but

slowly when impact at a velocity various from 30 to 80 m/s. Before

the parametric studies, inertial effect in various impact masses

was investigated. Comparison between parametric results showed that

the promotion on Specific Load and energy-absorbing capability

increases with the impact velocity for various honeycombs. Density

also has a great influence on Specific Load. The higher honeycomb

density is, the greater amplitude performs. The energy absorption

diagram for honeycomb with different geometric configurations

reveals the relationship between dynamic plane stress and energy

per unit volume, and also proves the promotion with increasing of

impact velocity.

Hexavalent chromium is remarkably versatile and exhibits many

desirable and essential characteristics through numerous metal

treatment processes such as zinc electroplating. After its initial

stage of dissolution, Hexavalent chromium then enters into a thick

trivalent chromium layer that controls color, thickness and a

“self-healing” property. Because of the “self-healing” property,

soluble hexavalent chromium compounds will re-chromate any exposed

areas when damaged. Finally, adsorption into the topcoat of the

hexavalent chromate completes the process.

Process

General process of an aluminum honeycomb core initiated with an

aluminum foil roll and surely the foil is specially treated.

The adhesive tapes are printed to the foil surface with the

intervals and width pre-determined by the cell size and strength

requirement.

The foil paper is cut into required size to be piled up on the

stacking table with equipment and man supervision on the adhesive

tape positioning.

These stacked loose blocks should be pressed in a heated press to

cure the adhesive so that the sheets of foil are bonded together to

hardened block.

The aluminum honeycomb block can be cut into slices with the height

of the slices tailored to customized requirements.

Finally, no matter it is done in supplier’s plant or at client’s

workshop, the honeycomb should be expanded before forming aluminum

honeycomb panel.

The following materials are for forming honeycomb cores:

1. Aluminum foil

Regularly, 3003H19/5052H18 aluminum alloy foils after strict

surface treatment are used for producing aluminum honeycomb core.

2. Special Purpose Chemical Adhesive

Modified epoxy glue for high temperature cure process can provide

not only sufficient bonding strength, but also environmental

resistance and high or low temperature resistant properties. The

joint strength of aluminum honeycomb core is the keypoint of

evaluating the core’s performance. The minimum requirement should

be more than 2.0N/mm.

Specification of Aluminum Honeycomb Core:

| Item | Unit | Specification |

| Cell Size | inch | | 1/8” | | | 3/16” | | 1/4” | | |

| mm | 2.6 | 3.18 | 3.46 | 4.33 | 4.76 | 5.2 | 6.35 | 6.9 | 8.66 |

| Side Length | mm | 1.5 | 1.83 | 2 | 2.5 | 2.75 | 3 | 3.7 | 4 | 5 |

| Foil Thickness | mm | 0.03-.05 | 0.03-.05 | 0.03- 0.05 | 0.03-.06 | 0.03-0.06 | 0.03-0.08 | 0.03-0.08 | 0.03-0.08 | 0.03-.08 |

| Width | mm | ≤440 | ≤440 | ≤440 | ≤1800 | ≤1800 | ≤1800 | ≤1800 | ≤1800 | ≤1800 |

| Length | mm | ≤1500 | ≤1500 | ≤2000 | ≤3000 | ≤3000 | ≤3200 | ≤4000 | ≤4000 | ≤5500 |

| Height | mm | 1.7~150 | 1.7~150 | 1.7~150 | 3~150 | 3~150 | 3~150 | 3~150 | 3~150 | 3~150 |

|

| Item | Unit | Specification |

| Cell Size | inch | 3/8” | | 1/2” | | | 3/4” | | 1” |

| mm | 9.53 | 10.39 | 12.7 | 13.86 | 17.32 | 19.05 | 20.78 | 25.4 |

| Side Length | mm | 5.5 | 6 | 7.33 | 8 | 10 | 11 | 12 | 15 |

| FoilThickness | mm | 0.03-.08 | 0.03-0.08 | 0.03-0.08 | 0.03-.08 | 0.03-0.08 | 0.03-0.08 | 0.03-0.08 | 0.03- 0.08 |

| Width | mm | ≤1800 | ≤1800 | ≤1800 | ≤1800 | ≤1800 | ≤1800 | ≤1800 | ≤1800 |

| Length | mm | ≤5700 | ≤6000 | ≤7500 | ≤8000 | ≤10000 | ≤11000 | ≤12000 | ≤15000 |

| Height | mm | 3~150 | 3~150 | 3~150 | 3~150 | 3~150 | 3~150 | 3~150 | 3~150 |

| | | | | | | | | | |

Specifications can be customized according to customer’s

requirement.

Applications of Aluminum Honeycomb Core:

1. Transportation: Interior and flooring panels for train, deck

panel and bulkheads in marine vessels and marine products,

automotive, truck and et al; shock absorber in train industry,

Crash test in automobile industry, tail windings and rotor blades

in copter and flooring in transit, ships, aircraft;

2. Construction: lightweight panels in building exterior and

interior, desk top, base, and shelving of furniture

3. Sports: bumpers and body panel of F1 machine

4. Manufacturing: industrial partition and tooling board.

5. Electrical: RF and EMI shielding; energy absorber

6. Energy: rotor blade in wind energy.

Supply modes of Aluminum Honeycomb Core:

- Unexpanded block

- Unexpanded slice

- Expanded sheet

- Pieces cut to size