High Flat Surface Aluminium Honeycomb Sandwich Panel Excellent

Weather Resistance

Product Discription

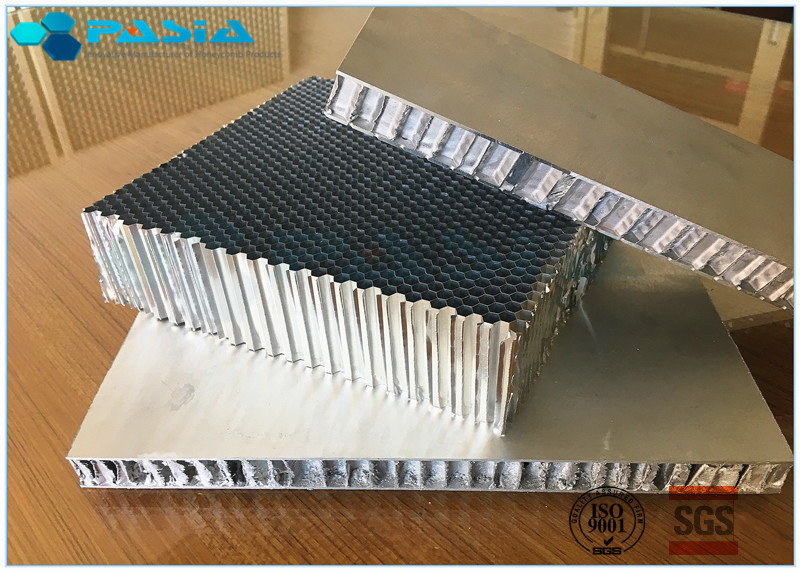

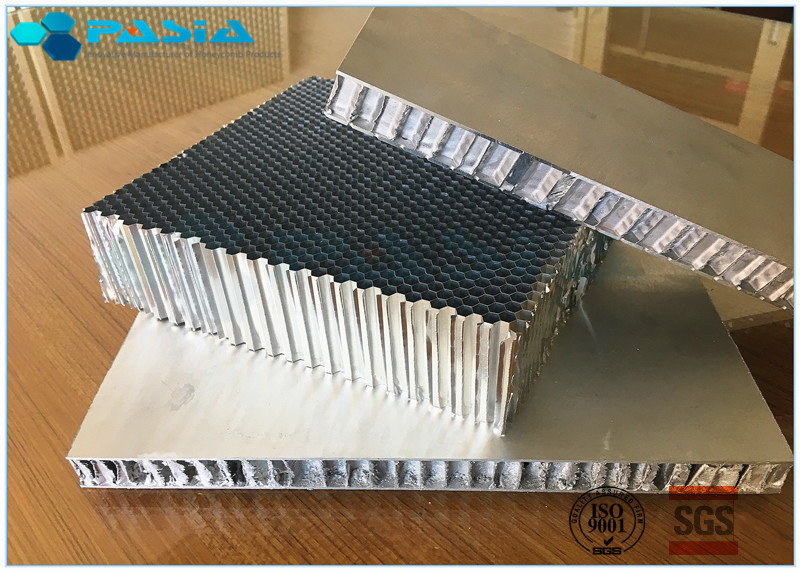

The inner material of the high-plane bonded aluminum honeycomb

curtain core board is an aluminum hexagonal honeycomb, and the

aluminum honeycomb core and the plate bottom plate of different

materials are combined to form a three-dimensional structural

material. The panel performs well in waterproof, moisture-proof,

and no harmful gas release, has a unit strength with high specific

strength and rigidity, is not easily deformed, and completely

overcomes the collapse and deformation of the central portion of

the large panel. The edge of the panel can be cut according to the

actual situation. PVDF coatings ensure product life is over 30

years.

The surface treatment of corrosion-resistant fluorocarbon resin can

be widely used in curtain walls, roofing, large facades, signs and

interior decoration. The front panel of the aluminum honeycomb

panel is coated with the E.C.C. quality standard PVDF fluorocarbon

coating with a common color or metallic color, so the surface has

excellent weather resistance.

| No. | Material | Thickness | Specification | Edge Treatment | Pre-treatment |

| 1 | Aluminium | 5mm | A3003 | Folded | Screw Enbedded |

| 2 | Aluminium | 10mm | A5052 | RHS Sealed | Perforated |

| 3 | Aluminium | 25mm | A2024 | Glue Sealed | |

| 4 | Aluminium | customized | A5056 | Open Edge | |

General Discription

Aluminum honeycomb panel is a bonded sandwich structure system of

two surface aluminium plates and one honeycomb cores with a special

purpose adhesive. Industrial used aluminium honeycomb panel will

add some more processes such as surface treatment, edging,

embedding, carving and so on to make the panel suitable for special

conditions. It has been widely used by the industries of civil

construction, transportation, exhibition, signage, elevator, clean

room etc. The honeycomb technology is from aerospace technology.

The whole production process is finished in the modern factory,

using hot pressing or vacuum pressing technology. Due to the high

thermal conductivity between the aluminum plates and honeycomb, it

is synchronized the thermal expansion and contraction of the inside

and outside aluminium material. There are small holes on the

honeycomb core foil wall so that the air is free of flowing inside

the panel box. Furthermore, sliding mounting buckle system does not

cause structural deformation during thermal expansion and

contraction.

Features

The center material is aluminum hexagonal honeycomb with a small

density (about 3 to 7 kg per square meter), about 1/5 of the weight

of wood with the same area and thickness, 1/6 of the glass, 1/7 of

solid aluminium, which greatly reduced the building load and

construction cost. Thanks to the air contained in the core, the

panel can be sound and thermal insulated. Because of no combustible

material contained, the fire rating can be at least B1 level. The

panel performs well also on waterproof, moisture-proof, no harmful

gas release, with a high unit mass of the specific strength and

stiffness, not easy to deformation, completely overcoming the

collapse and deformation in the center area if with large panel.

The panel edge can be cut depending on real conditions. The PVDF

coating can guarantee the product life more than 30 years.

After surface treated with corrosion resistant fluorocarbon resin,

it can be widely used on curtain wall, roof, large façade, signs

and interior decoration. The front plate of the aluminum honeycomb

panel is painted with E. C. C. A. quality standards PVDF

fluorocarbon paint with ordinary color or metallic color, so the

surface has excellent weather resistance.

In case of heavy rain, there is particularly large noise when the

raindrops hit the aluminum veneer or aluminum-plastic panel, while

honeycomb panel can avoid this situation. Aluminum honeycomb panels

are generally made of fluorocarbon coated aluminum plates. The

continuous roller coating with PVDF material is the most important

point to avoid color difference and flat coating film. Based on

this, it can keep the exterior building with bright color for long

time.

Application:

(1) building external curtain wall panel

(2) interior decoration works

(3) billboards

(4) ship building

(5) aviation manufacturing industry

(6) indoor partition and commodity display stand

(7) Commercial vehicle and container truck body

(8) bus, train and subway use

(9)With strict environmental requirements of the modern furniture

industry, aluminum honeycomb panel is an ideal material to produce

furniture. Depending on Its completely non-toxic green quality, it

is not necessary for the furniture manufacturers to process

environmental procedures. In addition, the surface veneer for

aluminum honeycomb panels can be diversified such as solid wood,

aluminum, gypsum board, natural marble etc

(10) aluminum honeycomb panel partition: the emergence of aluminum

honeycomb panel partition breaks the traditional partition mode,

with a noble and fresh style.