Stainless Steel Aluminum Honeycomb Panel for the Elevator or Lifter

Wall or Floor Panels

Product Description

The Stainless Steel Aluminum Honeycomb Panel for the elevator or

lifter wall or floor panels are with the regular stainless steel

solid panel performance but with much lighter weight and flatter

surfaces.

It possesses good properties as below:

Oxidation

High oxidation resistance in air at ambient temperature is normally

achieved with additions of a minimum of 13% (by weight) chromium,

and up to 26% is used for harsh environments. The chromium forms a

passivation layer of chromium(III) oxide (Cr2O3) when exposed to

oxygen. The layer is too thin to be visible, and the metal remains

lustrous and smooth. The layer is impervious to water and air,

protecting the metal beneath, and this layer quickly reforms when

the surface is scratched. This phenomenon is called passivation and

is seen in other metals, such as aluminium and titanium. Corrosion

resistance can be adversely affected if the component is used in a

non-oxygenated environment, a typical example being underwater keel

bolts buried in timber.

When stainless steel parts such as nuts and bolts are forced

together, the oxide layer can be scraped off, allowing the parts to

weld together. When forcibly disassembled, the welded material may

be torn and pitted, an effect known as galling. This destructive

galling can be avoided by the use of dissimilar materials for the

parts forced together, for example bronze and stainless steel, or

even different types of stainless steels (martensitic against

austenitic). However, two different alloys electrically connected

in a humid environment may act as Voltaic pile and corrode faster.

Nitronic alloys made by selective alloying with manganese and

nitrogen may have a reduced tendency to gall. Additionally,

threaded joints may be lubricated to prevent galling.

Acids

Stainless steel is generally highly resistant to attack from acids,

but this quality depends on the kind and concentration of the acid,

the surrounding temperature, and the type of steel. Type 904 is

resistant to sulfuric acid at room temperature, even in high

concentrations, type 316 and 317 are resistant below 10% and 304

should not be used at any concentration. All types of stainless

steel resist attack from phosphoric acid, 316 and 317 more so than

304; and Types 304L and 430 have been successfully used with nitric

acid. Hydrochloric acid will damage any kind of stainless steel,

and should be avoided.

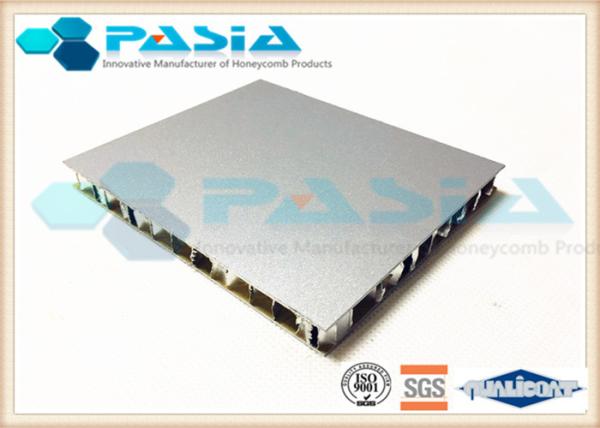

General Description

Stainless Steel Honeycomb Panel is comprised with two stainless

steel plates and one aluminum or stainless steel honeycomb core

layer. The upper surface can be colorful oxidation film coated or

diamond anti-skidding pattern stainless steel plates. The colorful

oxidation film performs well on corrosion resistance and cannot be

peered off by mechanical friction.

In metallurgy, stainless steel, also known as inox steel or inox

from French "inoxydable", is a steel alloy with a minimum of 10.5%

chromium content by mass.

Stainless steel does not readily corrode, rust or stain with water

as ordinary steel does. However, it is not fully stain-proof in

low-oxygen, high-salinity, or poor air-circulation environments.

There are different grades and surface finishes of stainless steel

to suit the environment the alloy must endure. Stainless steel is

used where both the properties of steel and corrosion resistance

are required.

Stainless steel differs from carbon steel by the amount of chromium

present. Unprotected carbon steel rusts readily when exposed to air

and moisture. This iron oxide film (the rust) is active and

accelerates corrosion by forming more iron oxide; and, because of

the greater volume of the iron oxide, this tends to flake and fall

away. Stainless steels contain sufficient chromium to form a

passive film of chromium oxide, which prevents further surface

corrosion by blocking oxygen diffusion to the steel surface and

blocks corrosion from spreading into the metal's internal

structure, and, due to the similar size of the steel and oxide

ions, they bond very strongly and remain attached to the surface.

Characteristics:

| No. | Properties |

| 1 | Variety of colors for selection with various of pattern |

| 2 | Good corrosion resistance, greatly better than the stainless steel

of the same type and the original color. |

| 3 | Heat Resistance, soaked in boiling water for 28 days or exposed at

the 200 °C for long time, no change on the color and luster. |

| 4 | Abrasion resistance and good scratch performance, no color change

after eraser friction more 2000 times at the pressure 500g/cm2. |

| 5 | film flexibility, after 180°T bend test and 8mm cupping test, film

is without any change. |

| 6 | Scrubbing resistance, applicable on washing with any organic

solvent, neutral detergent or water if there is dirt on the

surface. |

| 7 | Anti-pollution performance, the surface can be restored by washing. |

| 8 | aging resistance better than regular stainless steel |

| 9 | possessing advantages of the honeycomb panel: 1) lower density and

big flexural rigidity; 2) super flat surface; 3) good performance

on sound absorption and insulation as well as thermal insulation |

| 10 | safe on fire resistance: A2 grade |

| 11 | environmental: recyclable |

Application

Applicable on hotel, entertainment venues, high level exclusive

shops, elevator panel, hall wall panel, carriage panel, backdrop,

ceiling, decoration and signboard.