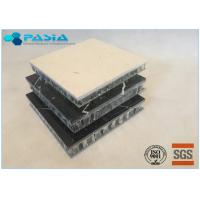

With more than 20 years’ experience on designing and manufacturing

honeycomb and metal product, Pasia Honeycomb Products Co. Ltd is

versatile on supplying diversified honeycomb and sandwich products

to clients of various industries including construction,

transportation, marine, industrial equipment, decoration and so on.

Honeycomb panels are applied and being applied in numerous fields,

based on the best strength and weight ratio, extreme condition

resistance such as high or low temperatures, humid or watery

condition and so on, A+ fire rating, high tolerance on size, etc.

Pasia has put into significant capital on equipment investment to

secure first class product fabrication. Until now, Pasia has

already possessed the most advanced bending machine, panel shearing

machine, digital controlled turret punch press, completely

automatically controlled continuous paint coating production line

and so on. It can not only mass produce flat panels, but also

produce single curved, twist and all shapes of customized honeycomb

panel. The production management is under ISO9001:2008 quality

management system. Quality products have won good reputation in

market with repeated orders from our customers. We have exported

our products to Germany, Brazil, Mexico, Colombia, Korea,

Singapore, Indonesia, Malaysia, Middle East, Uzbekistan, Russia,

Ukraine, Australia, Algeria, etc. Large scale production, effective

quality control system, complete local industry support and

advanced cost control plan make Pasia capable of providing

top-quality structural panels in wide variety of styles, designs

and materials at competitive pricing.

The company is now performing as a fast developing manufacturer on

R&D, designing, manufacturing and sales of honeycomb products

including aluminum or stainless steel, paper, Aramid, PP plastic

honeycomb core and their panels, stone honeycomb panels, innovation

honeycomb products, customized honeycomb products including section

inserted, painted, powder coated, oversized, special shape panels,

parts based on CAD drawing and so on.

Please contact with us if there is any queries on product, process,

property and so on. We will try our every best to deliver our

quality goods and services of your expection or beyond your

expectation.